Rear Load Garbage Truck 14 CBM is composed of sealed garbage compartment, hydraulic system and operating system. The vehicle is fully sealed. The water in the process of self-compression, self-dumping and compression enters the sewage tank, completely solving the problem of secondary pollution in the process of garbage transportation, and avoiding inconvenience to people.The key parts are imported parts, which have the advantages of high pressure, good sealing, easy operation and safety. Optional bucket hanging overturning mechanism or garbage hopper overturning mechanism.

Advantage

Mechanism Advantage

【Filling Mechanism】

The filling mechanism of the rear loader garbage truck(garbage compactor truck) is composed of a skateboard, a scraper and other components, and the garbage in the hopper is pressed into the box body through the sliding of the skateboard and the rotation of the scraper.

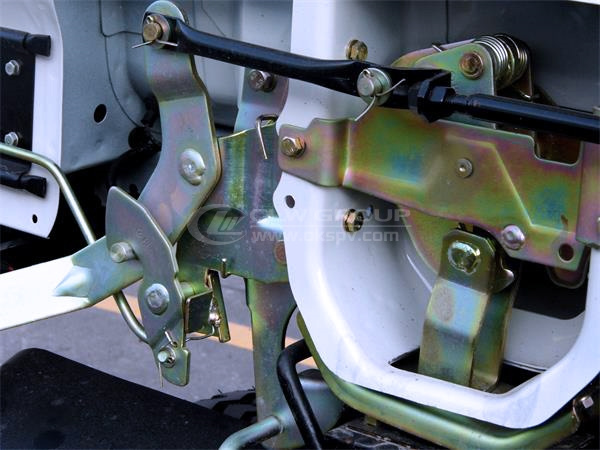

【Loading Device】

According to different garbage collection methods, users can choose to turn the drum type (it can hang the iron drum and plastic drum), the bucket type loading device and the swing arm type loading device.

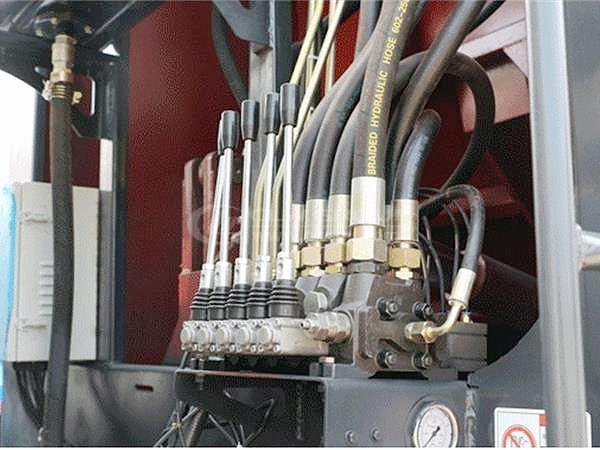

【Lifting Device】

The lifting device of the garbage compactor truck uses a hydraulic lifting circuit, and the valve blocks the direct connection of the lifting cylinder and the hydraulic hose.

【Garbage Collection Box】

The bottom of the box is equipped with a garbage collection box, so that the garbage in the box does not leak out, effectively preventing secondary pollution.

【Electronically Control】

The rear part of the box is electrically controlled, and adopts PLC integrated control. By setting a logic circuit, it ensures that each operation instruction is executed in order, and realizes automatic circulation work of the skateboard and the vertical board.

【Manual Operation】

The hydraulic controller at the rear of the cab controls the work of the overturning mechanism and filling mechanism to ensure the accurate and reliable action of each mechanism and improve the performance of the vehicle.

Chassis Advantage

【ABS】

The braking time and braking distance are shortened, which effectively prevents the vehicle from slipping and flicking during emergency braking, avoids violent friction between the tire and the ground, and reduces tire wear.

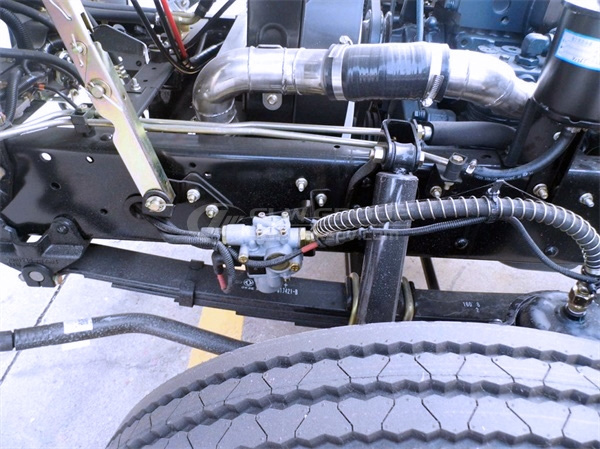

【Hydraulic Steering】

The steering wheel and steering wheel are connected by mechanical components for precise control. The hydraulic pump is driven by the engine, with sufficient steering power and high reliability.

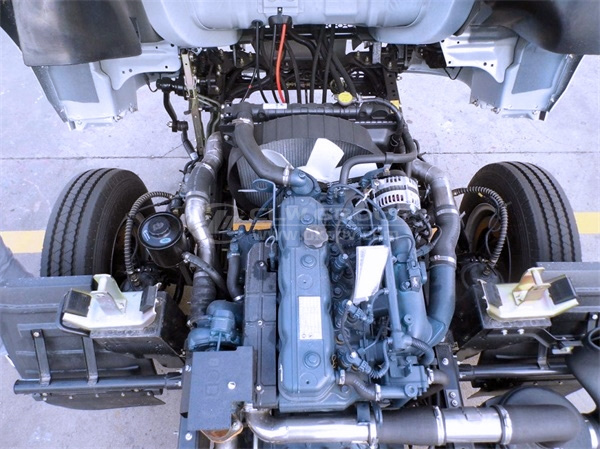

【Engine】

High-torque high-horsepower engine, strong power, 30% slope start without worry, low fuel consumption, environmental protection standards.

【Gearbox】

5-speed gearbox, more gears, adapt to complex road sections, easy shifting, economical and fuel efficient.

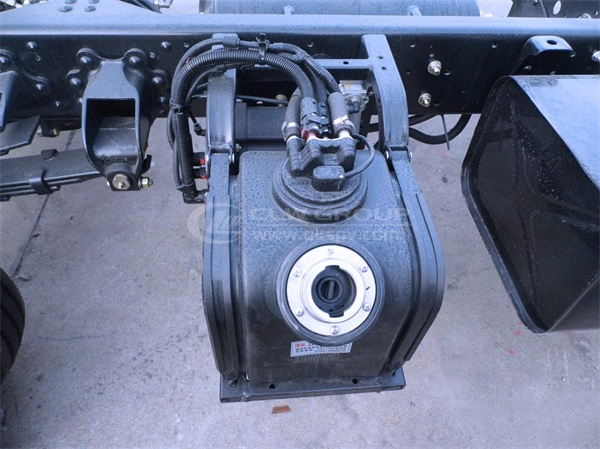

【Urea Tank】

Urea tank is used to store urea aqueous solution, selective reduction of SCR, reducing nitrogen compounds to meet the national five standards, more economical and environmentally friendly.

【Exhaust Gas Filter tube】

Leading technology, extending life by more than 28%. The addition of special active materials to the polar plates improves the charging performance by more than 15.6%.

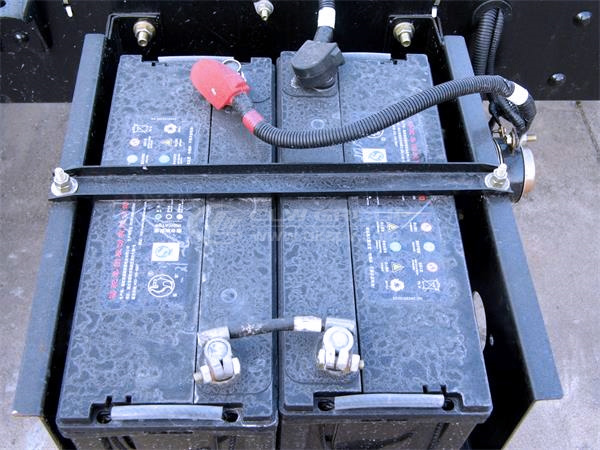

【Battery】

Leading technology, extending life by more than 28%. The addition of special active materials to the polar plates improves the charging performance by more than 15.6%.

【Air Condition Compressor】

Adjust the temperature and humidity in the car. An air-conditioning system that provides drivers with a comfortable environment, warm in winter and cool in summer.

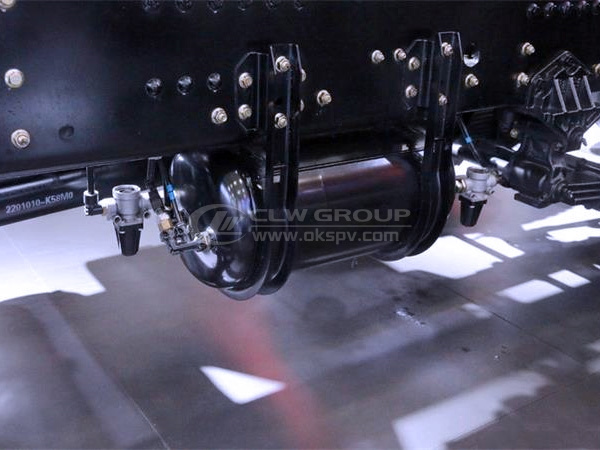

【Air Brake】

Compressed air enters the brake air chamber to lock the wheels, effectively preventing brake failure when the handbrake or mechanical failure of the drive shaft occurs. The brakes are more stable, more accurate and safer, and the uphill start is easy.

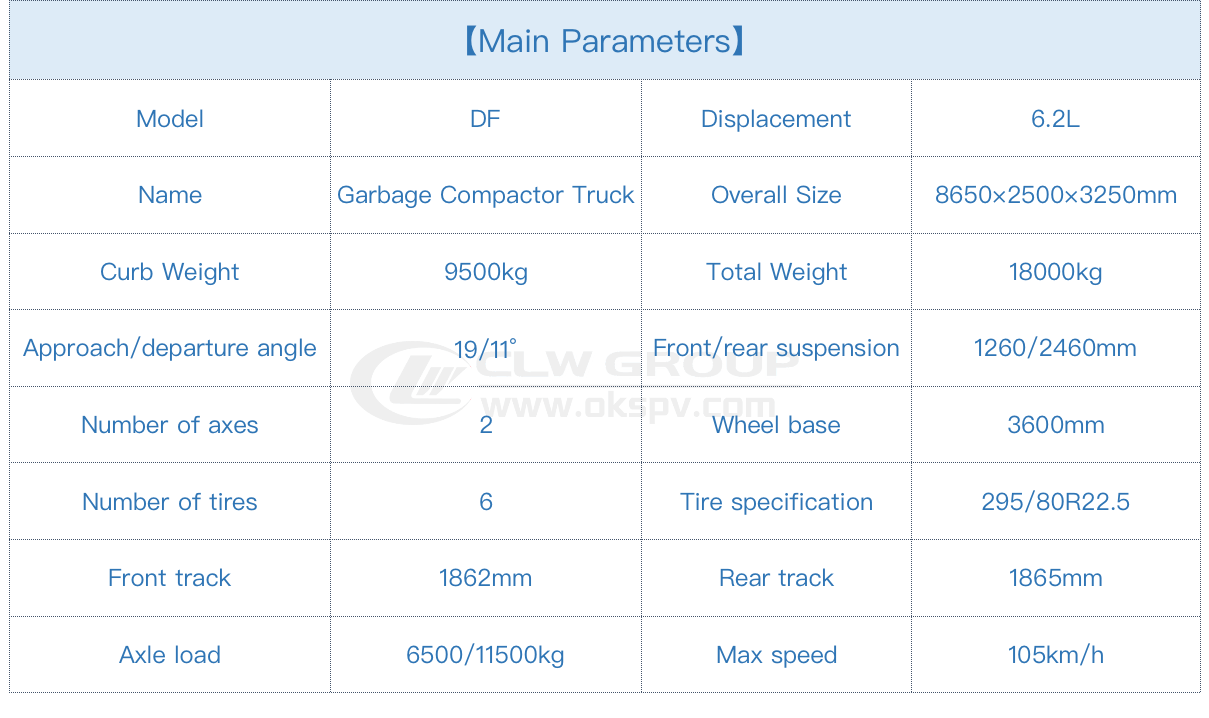

Specification

Top 10 SPV Manufacturer & Supplier - CLW Group

CLW Group is a professional special truck manufacturer & supplier. The company covers an area of more than 1,000 acres and employs more than 8,000 people, including more than 500 technicians, more than 2,000 skilled workers, and manufacturing more than 100,000 special trucks annually.CLW Group has been awarded as top 10 special truck manufacturer in China in 2018.

10 Online Inquiry