ISUZU compactor garbage truck use light & medium duty chassis of Japan ISUZU brand and adopts electro-hydraulic integration technology, mainly through the garbage compartment, filler, dozer, hydraulic system and other devices, with the help of the mechanical, electrical, and hydraulic combined automatic control system, through the compartment, filling special devices such as hoppers and dozers can realize garbage dumping, crushing or flattening, and powerful filling, squeezing garbage into the carriage, compacting and pushing off.

The main features of ISUZU compactor garbage truckare simple and efficient garbage collection methods, automatic repeated compression and peristaltic compression functions, high compression ratio, high loading quality, automatic operation, good power and environmental protection, high efficiency of vehicle utilization, and good airtightness.

Advantage

【Sealed Garbage Compartment】

On the right side of the front of the compactor garbage compartment, there is a feeding port and an automatic lifting and loading device. There is an automatic door at the rear of the compartment, which can be opened automatically when unloading. High-quality steel plates are used in manufacturing. Stainless steel plates can be added to the bottom of the compartment to ensure smoothness during self-unloading of the medium. At the same time, the bottom of the compartment can be equipped with anti-icing settings according to the seasonal temperature of the region to ensure normal operation of the truck.

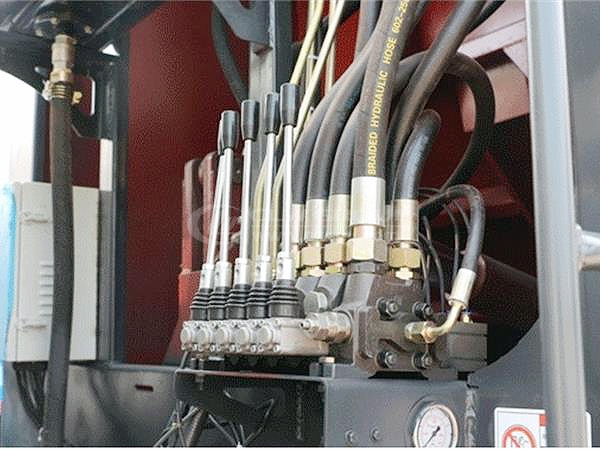

【Hydraulic System】

Through this system of the compactor garbage truck, special functions for automatic lifting and unloading can be realized. The use of high-quality lifting cylinders, operating valves, compression fittings, high-pressure hoses and high-pressure steel pipes are reasonably installed. At the same time, reliable fixing devices are arranged to ensure that there is no leakage for a long time, to achieve reliability, easy maintenance and prolong service life.

【Diversified Overturning Mechanism】

Including diversified flipping (barrel) systems such as rear-hanging bucket type and trash can type, which can lift trash cans of various capacities. It can tip over 300L trash iron bucket, 800L small trash hopper, 250L plastic trash can, 1400L sealed trash hopper and etc.

【Hydraulic Lifting Safety Circuit】

The explosion-proof valve in the hydraulic lifting system of this compactor garbage truck effectively blocks the hydraulic hose and the lifting cylinder. In the event of a pipe rupture, there will be no danger and it is relatively safe.

【Electronically Control】

The rear part of the box is electrically controlled, and adopts PLC integrated control. By setting a logic circuit, it ensures that each operation instruction is executed in order, and realizes automatic circulation work of the skateboard and the vertical board.

【Manual Operation】

The hydraulic controller at the rear of the cab controls the work of the overturning mechanism and filling mechanism to ensure the accurate and reliable action of each mechanism and improve the performance of the vehicle.

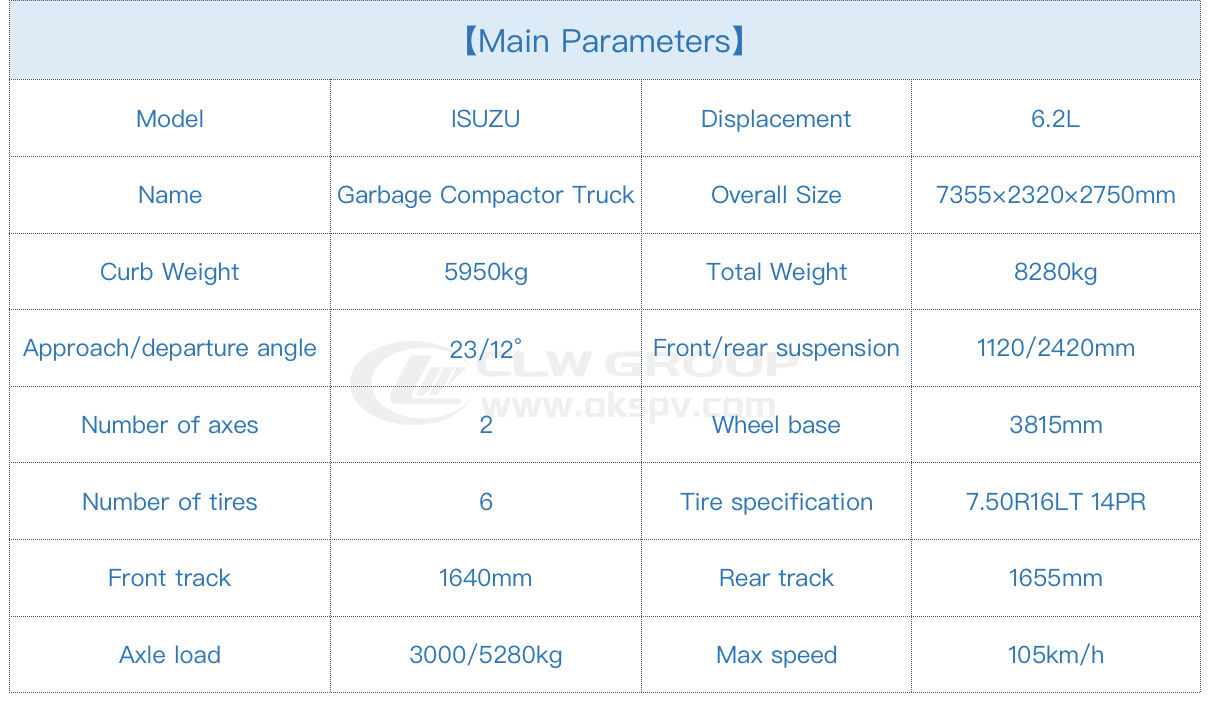

Specification

Top 10 SPV Manufacturer & Supplier - CLW Group

CLW Group is a professional special truck manufacturer & supplier. The company covers an area of more than 1,000 acres and employs more than 8,000 people, including more than 500 technicians, more than 2,000 skilled workers, and manufacturing more than 100,000 special trucks annually.CLW Group has been awarded as top 10 special truck manufacturer in China in 2018.

10 Online Inquiry